Telescopic Sliding Gates

Automatic Telescopic Driveway Gates

Sliding Driveway gates are a popular choice because they don’t take up valuable driveway space, they can span wide driveways and aren’t affected by slope up from the road but they do need space to open, what if there’s not enough? We offer sliding gates that can have multiple panels typically two although can have three or four too that stack one on front of the other requiring less space to open. They can be shaped to fit driveways that slope across too see Sliding Gates on Sloping Driveways. If you’re planning on installing a telescopic gate and want to just get footings in place for now see: Footings for Telescopic Gates

Australia Wide Shipping

After Sales Support

Quality Guarantee

Authorised Supplier

Telescopic Gate Designs

Two and Three Panel Telescopic Gates

The most popular type of sliding gate when space to open is limited is a two panel sliding gate with one panel stacked in front of the other, commonly known as ‘Telescopic Gates” or “Stacker Gates”.

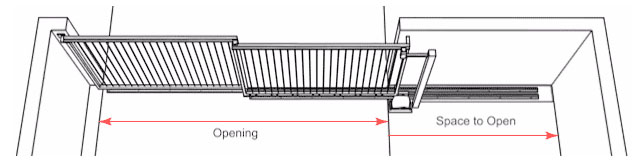

Two Panel Telescopic Gates

Space to open two panels is: 1/2 Opening + 200mm to 300mm typically:

A 3m wide two panel telescopic gate can open into 1.7m.

A 6m wide two panel telescopic gate can open into 3.4m.

If there’s still not enough side room to open a telescopic gate may have three panels.

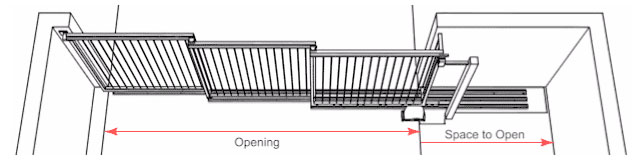

Three Panel Telescopic Gates

Space to open three panels is: 1/3 Opening + 200mm to 300mm typically:

A 3m (10′) wide three panel telescopic gate can open into 1.2m.

A 6m (20′) wide gate can open into 2.3m.

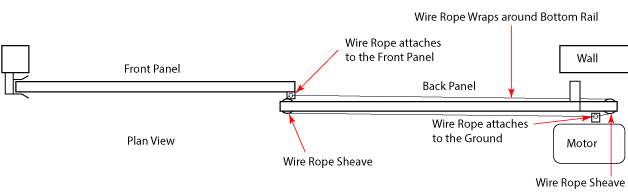

How Telescopic Gates Work

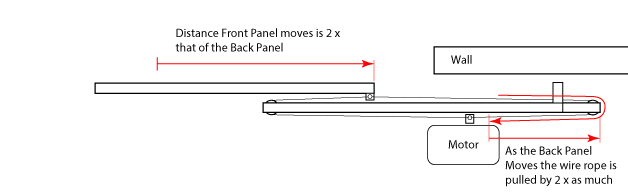

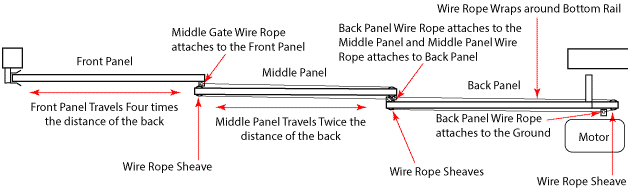

The back gate panel is driven by motor like a single panel sliding gate is. A telescopic drive mechanism then drives the front gate from the back using a wire rope that wraps around the bottom rail connecting to the ground at one end and the front gate at the other end. There is a sheave (like a pully but for wire rope) fitted to each end of the bottom rail.

As the back gate opens the wire rope pulls the front gate panel along by twice as much as the back so it travels at double the speed and goes twice as far ending up directly in front of the back gate when open. The same occurs with the second half of the wire rope when closing.

Optimising Side Room to Open a Telescopic Gate

If you want to get a telescopic gate to open into the smallest amount of space possible there are a number of factors in the design of the gate, guide system and motor that can help.

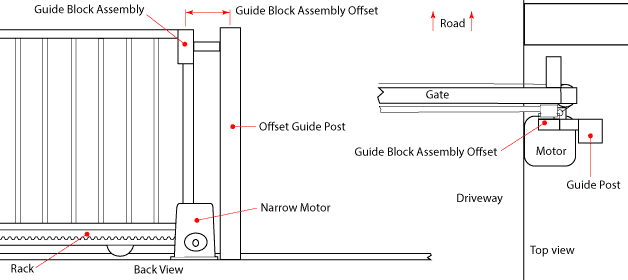

- Use a motor that is only 200mm wide that requires nothing fitted to the rack. This eliminates the need for an extension to the bottom rail because telescopic gates need to overlap the front fence by at least 125mm anyway and this is enough for a motor like this to work.

- Place any guide post on the opposite side of the gate motor than the driveway so the motor can be as close to the driveway as possible. The guide channel and block can then be offset so it still lines up with the gate and no extension to the top rail is required either.

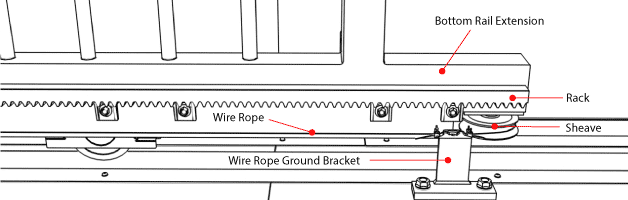

- The sheaves for the wire rope should be cut into the bottom rail so the overlap between the gate panels can be as small as possible, ideally 85mm and bottom rail extension (if any) is as small as possible.

Drive Mechanism Between the Gate Panels

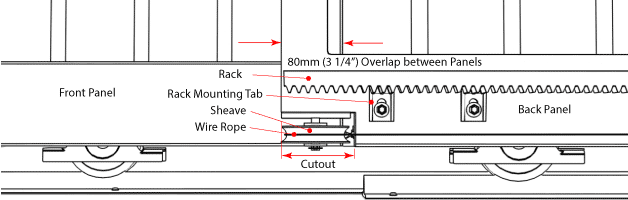

If the sheaves for the wire rope are cut into the bottom rail this enables only an 85mm overlap between gate panels that helps keep the amount of side room the gate requires to open to a minimum. When fitting the rack the mounting tabs for the rack need to be as close to the sheave as possible so the rack itself can span above the sheave cut out.

A simple mounting bracket for connecting the wire rope to the front gate panel must be inline with the centre of the sheave with the mounting point on the bracket as close to the back panel as possible.

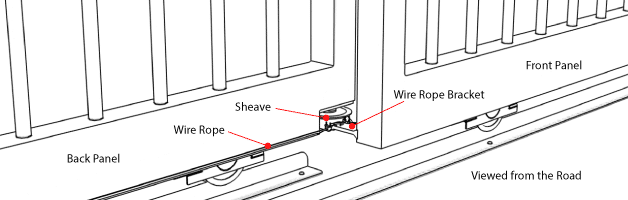

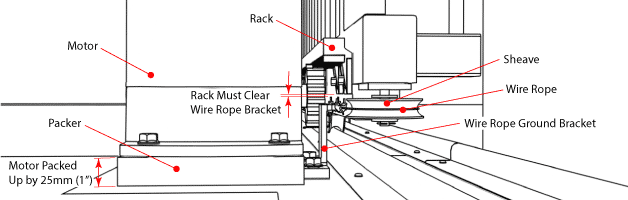

Drive Mechanism at the Motor End of the Back Gate Panel

Same goes for the sheave at this end too, cut into the bottom rail with rack carefully positioned and a wire rope bracket that fits to the ground with it’s mounting point in line with the centre of the sheaves and as close to the back panel as possible.

The rack must clear the wire rope ground mounting bracket so the motor needs to be packed up, normally by 25mm if on flat ground or other height if the ground slopes. This can be done using box sections of aluminium.

Drive Mechanism for Three Panel Telescopic Gates

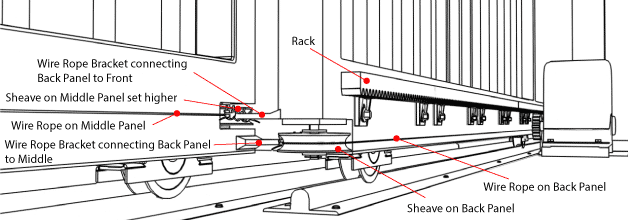

A three panel telescopic gate has a second wire rope drive mechanism that wraps around the middle gate that connects the back gate to the front gate with the middle gate pulling the front gate by four times as much as the back.

The wire rope drive mechanism on the middle panel must be set higher than the one for the back panel, so they don’t clash. Because the middle gate has no rack it can go as high as necessary.

Guide System for Telescopic Gates

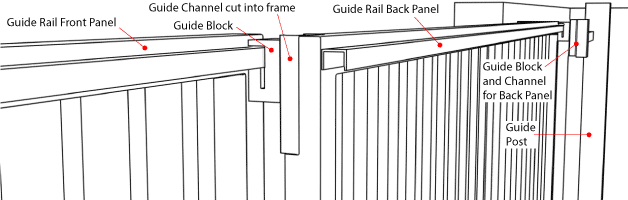

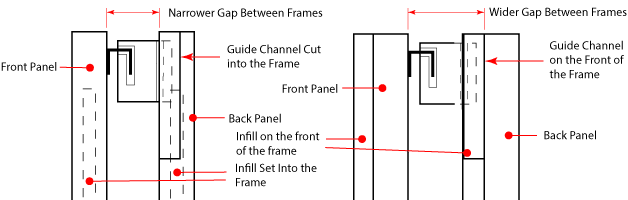

The guide system uses a standard guide block and rail system for both panels. For the front panel the guide channel is fitted to the back panel cut into the frame to keep the gap between panels to a minimum. Guide rails are normally only 25mm x 25mm to also keep the gap between panels to a minimum.

If the gate has slats or similar material fitted to the front of the frame the guide channel won’t need to be cut in or can be packed out to allow for battens fitted to the front of the frame require more space.

The Return Panel for Telescopic Gates

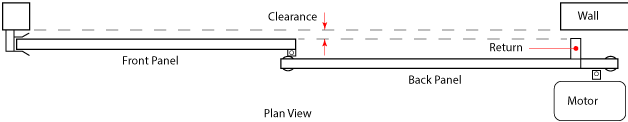

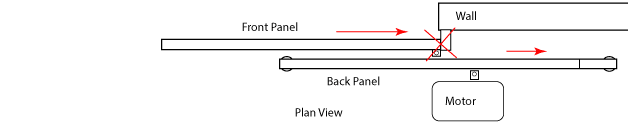

When a telescopic gate is closed there is clearance between the fence or wall and gate although the back is is set further back so to prevent there being a larger gap a small return panel is added to fill this gap in.

If the return was attached to the fence or wall it would obstruct the front panel once it opens about half way so needs to be on the back gate so it moves out of the way as the gate opens.

Telescopic Gates on a Slope

When there is limited space a gate can be made up as two or more panels that stack one in front of the other that are commonly called Telescopic or Stacker gates and can be on a driveway that slopes across.

The bottom rail of both gate panels must be raked (sloped) to fit the slope of the driveway with the telescopic drive mechanism built into the bottom rail of the back panel at an appropriate angle (and middle for three panels). The top can also be raked, either the same slope as the bottom or at a different slope although the guide block and channel must be angled square to the top rail as it is with single panel sliding gates.

Level Top Telescopic Gates Opening Down Hill

When there is limited space a gate can be made up as two or more panels that stack one in front of the other that are commonly called Telescopic or Stacker gates and can be on a driveway that slopes across.

The bottom rail of both gate panels must be raked (sloped) to fit the slope of the driveway with the telescopic drive mechanism built into the bottom rail of the back panel at an appropriate angle (and middle for three panels). The top can also be raked, either the same slope as the bottom or at a different slope although the guide block and channel must be angled square to the top rail as it is with single panel sliding gates.

Level Top Telescopic Gates Opening Up Hill

A telescopic gate with a level top that opens uphill has guide rails rising up as the gate opens so they need to be lower down so they don’t rise above the top of a back panel or fence. The amount each guide rail rises with a two panel telescopic gate is half that of a single panel sliding gate, three panel are a third.

The panels may also be stepped keeping the size of each panel much the same, ideal for steeper slopes, although the guide channel between panels should be lower than the panel in front so it’s not seen above this panel when the gate is closed as this doesn’t look nice.

To calculate the size of motor required for telescopic sliding gate on a slope

With a two panel Telescopic gates because the front gate is being propelled at twice the speed as the back and both are being propelled by one motor the effective weight of the gate is 1.5 x that of a single piece sliding gate of the same weight.

With three panel telescopic gates because the front gate is being propelled at four times the speed and the middle gate at twice the speed of the back gate the effective weight is 2 1/3 times that of a single panel sliding gate the weight.

If a sliding gate is on a slope across the driveway the effective weight increases significantly so a much larger motor is needed but also the type of motor is important too. A 240V single phase motor is NOT suitable for sliding gates on a slope, 12VDC and 24VDC motors work well and Three phase motors with a variable speed inverter drive work the best.

Please contact us for advice on the best motor for sliding gates on a hill.